Q1 - How does a orifice flow meter work?

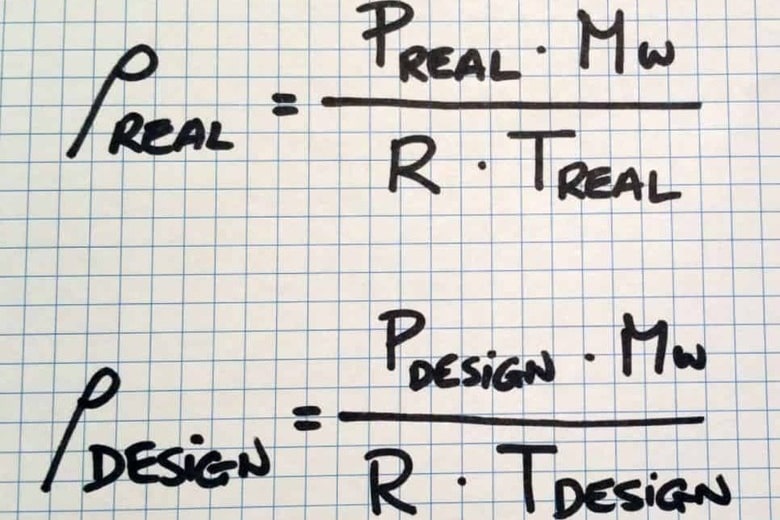

An orifice flow meter operates based on the principle of measuring the differential pressure across a

constriction in a pipe. It consists of a circular orifice plate with a precisely drilled hole installed in the

pipe, which causes the flow to constrict as it passes through. As fluid flows through the orifice, its velocity

increases, and the pressure decreases. The pressure differential between the upstream and downstream sides of

the orifice is proportional to the flow rate. This differential pressure is measured using pressure sensors,

such as a differential pressure transmitter. By applying the Bernoulli equation, the flow rate can be calculated

using the measured pressure drop. The orifice flow meter is suitable for measuring the flow of liquids, gases,

and steam.

Q2 - How to calibrate orifice flow meter?

Calibrating an orifice flow meter is crucial to ensure accurate measurements. The calibration process involves

comparing the actual flow rate with the flow rate indicated by the flow meter. This is typically done in a

controlled environment using a reference standard, such as a master flow meter or a volumetric flow standard.

The calibration involves adjusting the meter's coefficient (known as the discharge coefficient) to account for

any discrepancies between the indicated and actual flow rates. The technician may also calibrate the

differential pressure transmitter to ensure accurate pressure readings. Regular calibration is essential to

maintain the accuracy of the orifice flow meter over time.

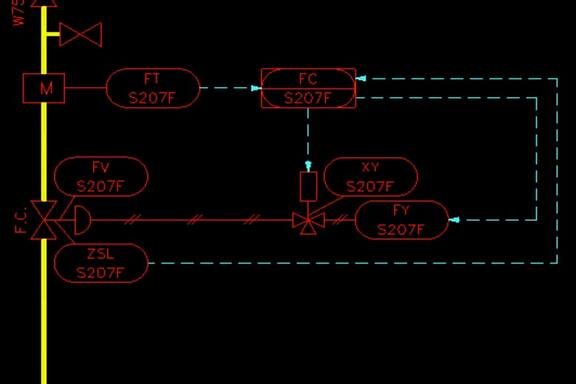

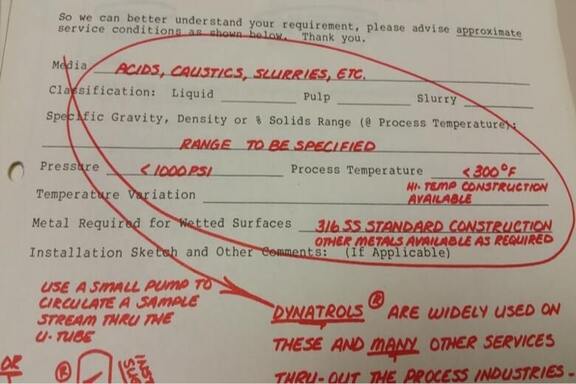

Q3 - How to design orifice flow meter?

Designing an orifice flow meter involves selecting the appropriate orifice plate size, shape, and material based

on the fluid properties and the required flow measurement accuracy. The design also includes determining the

location for installation, which is typically a few pipe diameters downstream of any disturbances like bends or

valves. Additionally, the design should consider the use of a differential pressure transmitter and associated

instrumentation for pressure measurement. The orifice plate dimensions, including the orifice diameter and the

downstream tapping location, must adhere to recognized industry standards, such as ISO 5167. Proper design

ensures accurate and reliable flow measurements.

Q4 - Can flow meters be installed vertically?

Flow meters can be installed vertically under certain conditions. The orientation of a flow meter depends on the

type and design of the flow meter and the specific application. Many flow meters, including orifice flow meters,

can be installed vertically, but they must meet certain criteria. When installing a flow meter vertically, it's

important to consider factors such as the flow direction, the effects of gravity on the fluid flow, and any

potential air or gas pockets that may develop in the line. Proper installation and orientation are critical to

ensure the accurate measurement of flow, and manufacturers' guidelines and industry standards should be followed

to determine the suitability of vertical installation for a particular flow meter in a given application.