Pressure and Temperature Flow Compensation Formula and equations

What is pressure compensation? Why temperature compensation is required?

1. Pressure and Temperature Flow Compensation Formula and equations

1.1. What is pressure compensation? Why temperature compensation is required?

This article allows us to understand what is the relationship between the flow measurement, the pressure and the temperature of a fluid. This article shows how the flow measurement is compensated when we have a flow measurement that does not automatically compensate for differences in fluid pressure and temperature. If you are interested in making a hole plate calculation you can visit our calculator pages to make the calculation and download the result in a spreadsheet.

2. Contents

- What is Flow Compensation?

1.1. Formula for pressure - Obtaining the Real Density Formula

- Deriving the Differential Pressure Flow Equation

- Pressure Temperature Compensation Formula (steam or gas flow compensation formula)

- References

3. What is Flow Compensation?

3.1. Why do you do process temperature and pressure flow compensation?

In steam or gas flow measurement, the density of the steam or gas changes as pressure and temperature change. This change in density can affect the accuracy of the measured flow rate if it is uncompensated. Temperature, pressure compensated flow control is a flow modified mathematically by one or more additional variables, like:

- Temperature

- Pressure

- Density

- Viscosity

Producing a resultant value for flow compensation that is more accurate. It is compensated for the error effects of the other variables.

3.2. Formula for pressure

This post is related with how to compensate flow with pressure and temperature. If you are looking for the Pressure Formula click here!

Why do you do process temperature and pressure flow compensation?

4. Pressure Temperature Compensation Flow Measurement Formula

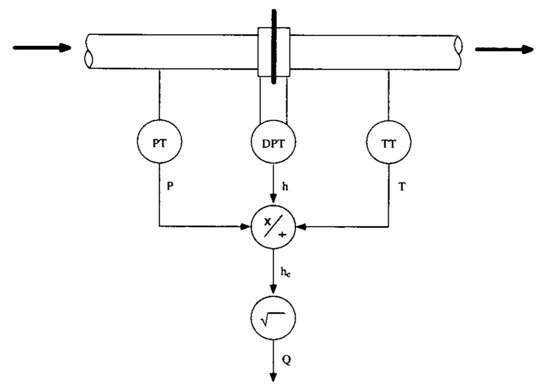

Orifice meters require Pressure Temperature Compensation Formula when we use them to measure steam or gas flow in pipes with variable operating pressure and temperature. Normally we do not have an online density measurement. In this case we will consider the density constant to simplify the calculations. If you want to perform a density compensation in the flow measurement you must take into account the density variation.

The variations in pressure and temperature have a significant effect on steam or gas density, this is why without this pressure and temperature compensation the flow measurement can have large errors.

This post will help you to understand the basics concepts around this formulas (flow compensation formula) and will also let you implement them on your process control system.

5. Obtaining the Real Density Formula

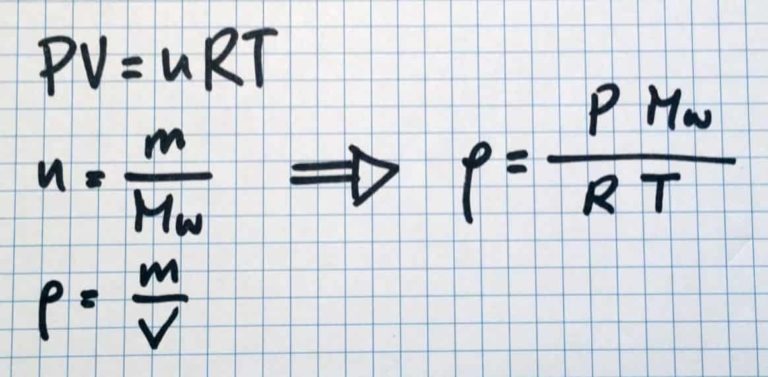

Starting with the ideal gas law, we can extract density from the formula and calculate the density for two different situations (design and real). We need to apply a density compensation in flow measurement.

where:

- P = Pressure

- T = Temperature

- V = Volume

- Mw = Molecular Weight

- n = Number of mols

- R = Gas constant

- rho = steam or gas density

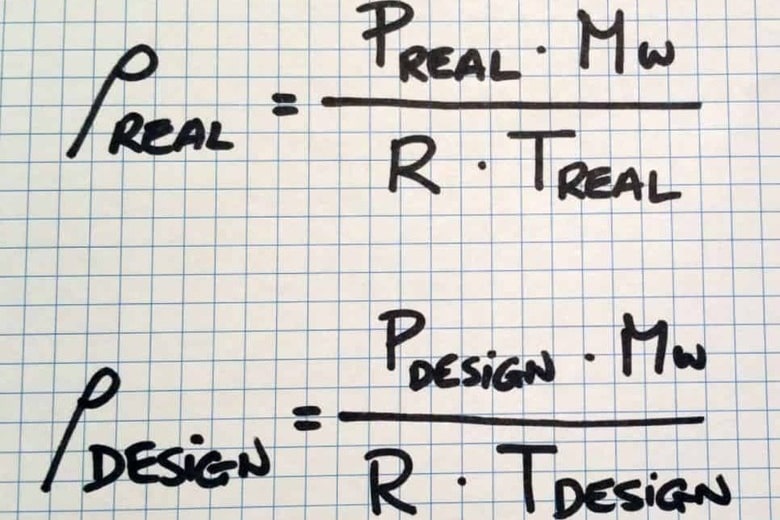

After simplifying the previous equation we can have different results depending on the different situations, so we can have a set of design conditions and also a set of real situation conditions.

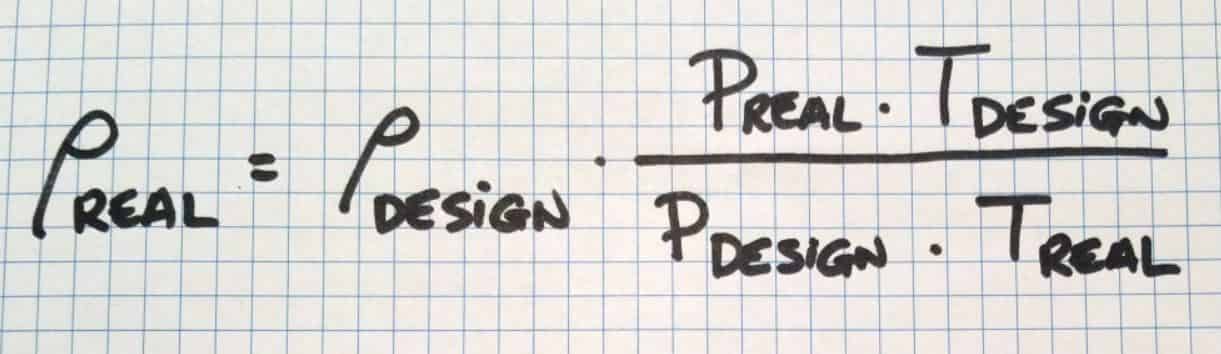

Operating with the formulas for real density formula and design density we can obtain the formula to define the real density taking into account the pressure and temperature compensation.

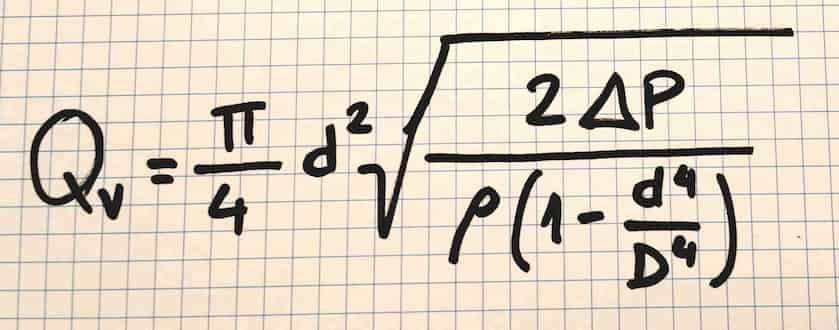

6. Deriving the Differential Pressure Flow Equation

To obtain the Differential Pressure Flow equation we will use two basic fluid mechanics equations: Eulers equation of continuity and Bernoullis principle.

Where:

- V = linear velocity of fluid

- rho = steam or gas density

- A = Area

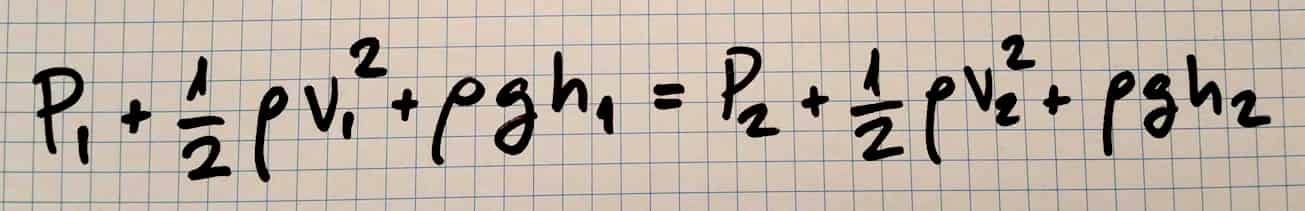

And:

Where:

- P = Pressure

- rho = steam or gas density

- V = linear velocity of fluid

- g = standard gravity

- h = height

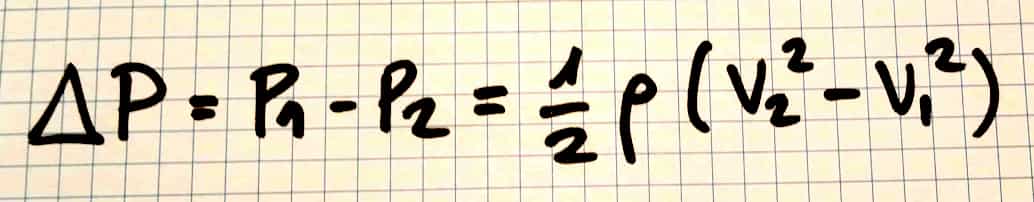

Rearranging the previous equation and assuming constant density and h1=h2 we have ....

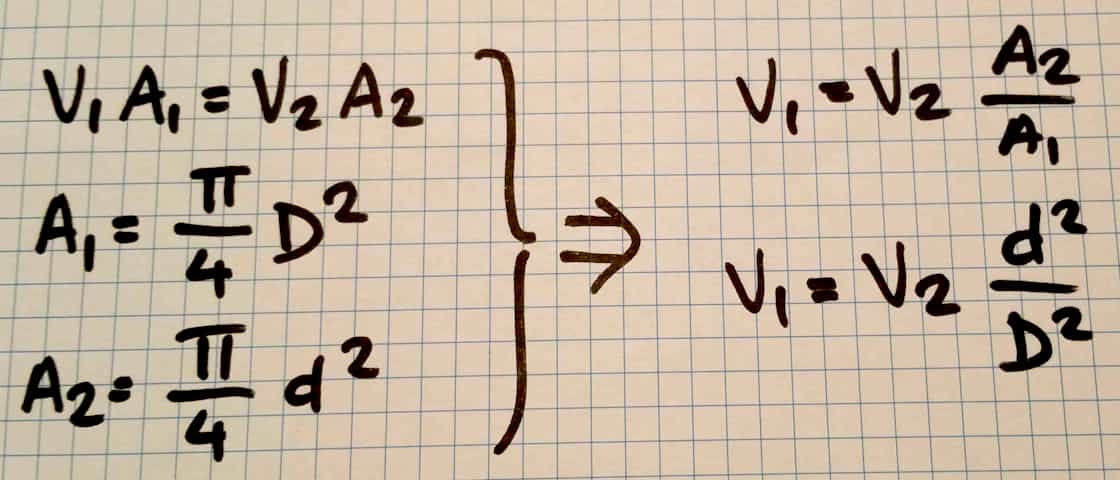

Now its time to express fluids velocity in function of pipe diameter (D) and orifice (d) plate restriction diameter:

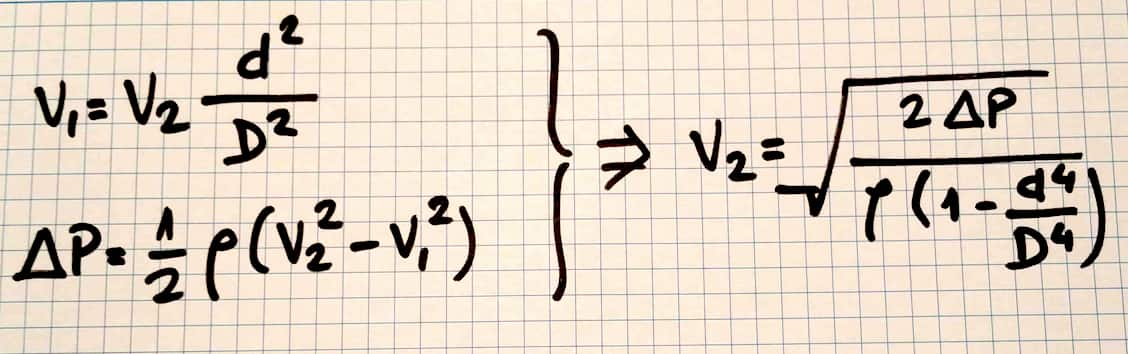

and after that, we can substitute V1 inside the previous equation, the resulting equation gives us the velocity at the restriction:

To calculate the volumetric flow we have to multiply both sides by the area of the restriction:

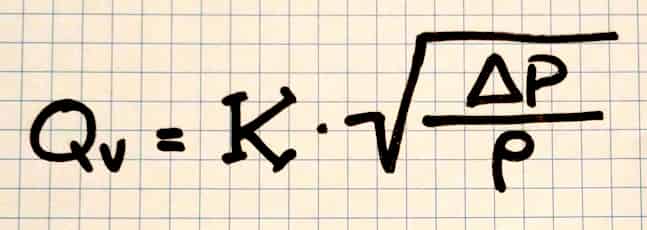

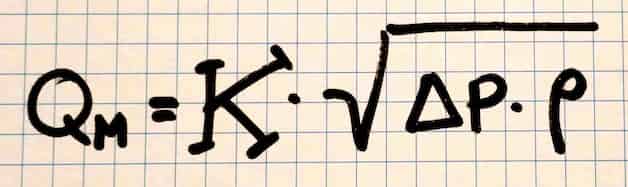

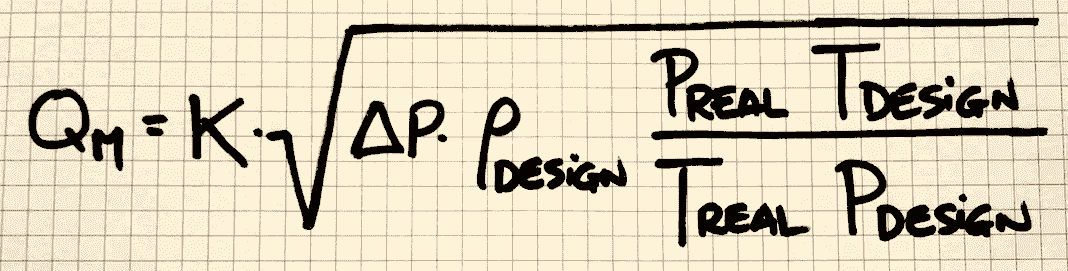

If we concentrate all the constants in just constant called K we have the following expressions referring to QV and QM:

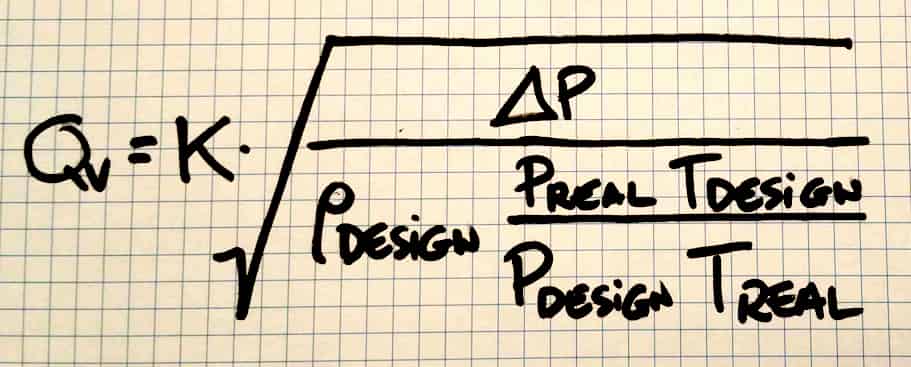

7. Pressure Temperature Compensation Formula (steam or gas flow compensation formula)

7.1. How does pressure compensated flow control work?

Now its time to substitute the real density by the density calculated in point 2.

After the substitution we will have the following formulas which are used to calculate the compensated flow for every orifice plate flowmeter (depending if you need volume or mass flow).

Remember that you must use the flow square root extraction formula in your DCS!!!