P&ID Symbol Diagram Basics - Part 3

Functional Identification and Naming Conventions

1. Introduction to P&ID Diagrams

Other related articles:

- If you are interested to know more about subjects like Purpose, Owner and Contents & Conventions, read our free introduction to these concepts in our article P&ID Diagram Basics Part 1 Purpose, Owner and Contents.

- If you are interested to know more about subjects like Standards and Guidelines read our free introduction to these concepts in our article P&ID Diagram Basics - Part 2 - International Standards.

- If you are interested to know more about subjects like P&ID Symbols read our free introduction to these concepts in our article P&ID Diagram Basics - Part 1 - Symbols - How to read a P&ID.

Engineers like to draw and create outlines of their ideas.

It is usually necessary to be able to explain your ideas to your clients or collaborators. Many times we use drawings to explain an idea that otherwise would require many words to be explained.

During my years as an automation engineer I have made some good drawings that have helped me to better explain my ideas.

Once the drawing is done, it is necessary to identify the elements present in the P&ID diagram in order to relate them to reality. It is about this concept that this article deals with.

This third article on P&ID diagrams deals with the functional identification and the conventions when naming the elements present in a P&ID diagram.

The reason is quite simple, users of instrumentation and control systems need some method to identify the equipment so that they can administer the engineering, the purchases, the installation and the maintenance of those systems.

But the identification must follow some basic rules to have a good documentation. Good documentation is the basis for good engineering and good maintenance of the facilities.

The identification standard of the elements connected to the process control for most industrial installations is based on ISA-5.1.

Sometimes however, you will find that additional information or interesting interpretations are added to better define the local requirements, to meet the specific requirements of the system or even to maintain the tradition of the site.

It is very important that the standards used in your facilities are fully defined and rigidly followed. The tag guidelines should be uniform throughout the plant.

Also, most major companies have their own internal standards. Whilst there are many differences in detail between them, the basic symbols and letter code structure are essentially the same. If there is no standard set by the factory, the symbology will normally be based on the ISA-5.1-1984 standard (R1992).

There are several national standards which relate to the representation of instrumentation and control schemes. The most important English language ones are BS 1646 and ISA S5.1.

2. P&ID Functional Identification General Rules

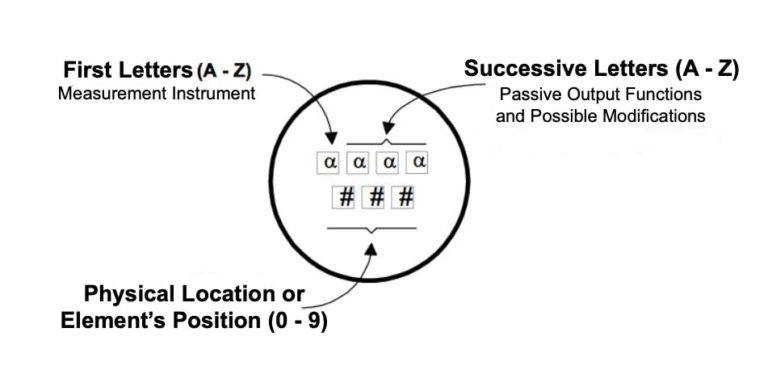

- All the symbols that appear in a P&ID diagram are formed by combinations of letters and numbers. A certain amount of judgment is required to establish the most appropriate letter code for an element. Combinations of letters and numbers appear in each p&id symbol.

- The meaning of the letters of the prefix of the label depend on the position. These letters, in general, contain enough information to transmit the functionality of the control loop and allow to understand the meaning of the measurement and control. Sometimes, the code of the letter is insufficient to give an adequate description of the function of an element, if it is not enough you can provide additional information, either in a box attached to your bubble or as adjacent text.

- The loop number is unique to each loop. The loop number is typically common to all instruments within a loop.

- All instruments and elements will be identified according to function, and should contain the loop numbers. The letters are a shorthand way of indicating the type of instrument and its function in the system. Typically, two or three letters are used. The first letter identifies the measured or initiating variable, the second letter is a modifier, and the remaining letters identify the function.

- The letter codes must be assigned according to the function. As a general rule, the functional identification of an instrument will be made according to the function and not according to its construction. Then we must select the code of the letter taking into account the function of the element and not by its design or installation. For example, cell dp in the accompanying figure is designated as a level transmitter LT-S233A instead of PDT S233A even though it measures differential pressure. ISA-5.1-1984 (R1992), advises that the identification of the instruments be made according to the function and not to the construction. It is broad in scope and flexible in usage.

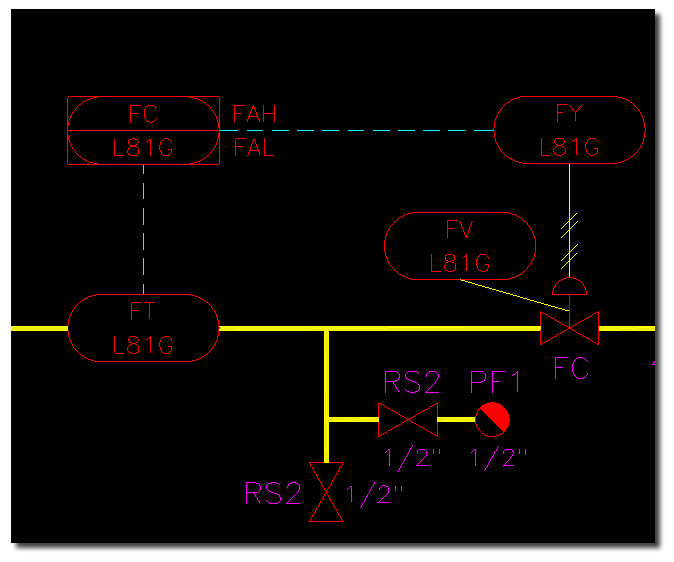

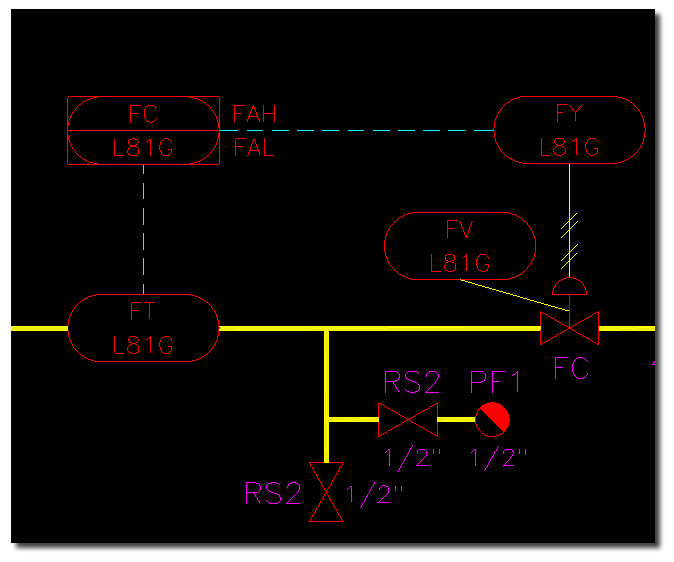

- The first letter of a functional identification refers to the measured variable. Therefore, the valve positioner is designated as FY L81G, although its input is a current and its output a pressure. This first letter corresponds to the measured variable and, if necessary, can be qualified by a modifier. Successive letters describe the reading or control functions of an element and these may have modifiers.

- Rule of thumb The total number of letters in a tag number should not exceed four.

- According to ISA, it is incorrect to use the letters CV for a function other than a self-acting control valve.

- In order to keep the P&ID diagrams clear and simple, the complex logic is not shown, this is shown in the logic diagrams ISA-5.2-1976 (R1992).

3. P&ID Functional Identification Tagging

The tagging process is well documented process defined in several standards, the typical tag number consists of two parts:

- a functional identification or prefix

- and a loop number or suffix

Depending on the circumstance, the second set of letters are used for indication and record. They can also be used as a noun, verb, or adjective, in which case they will appear in text or speech as Indicator, Recorder, Indicating, and Recording.

The two-element numbering scheme corresponds to the following format:

where XXXX is the tag prefix that provides indication of function and YYYY is a sequential identifier to make the tag unique.

Sometimes a middle element, such as a building number or a process material designator, is inserted to indicate a process area.

3.1 Prefix

The prefix is the important part of the identifier. In the majority of the standards related p and id tagging methods, the tag prefix letters are position dependent.

The first letter indicates the physical property being measured or controlled (e.g., pressure, flow, temperature). The first letter of the tag number is normally chosen so that it indicates the measured variable of the control loop.

In the sample P&ID diagram shown in the above figure, F is the first letter in the tag number that is used for the instruments in the flow control loop. The functional identification consists of a first letter (designating the measured or initiating variable; for example, F for Flow, T for Temperature, etc.).

The second or third letters are modifiers. In the above figure, the F in the first position indicates a flow control item. FT in the leftmost bubble indicates the item is a flow transmitter. FC is a flow controller, FY symbol is an I/P transducer, and FV is a flow control valve.

The line across the center of the FC balloon symbol indicates that the controller is mounted on the front of a main control panel or DCS. No line indicates a field-mounted instrument, and two lines means that the instrument is mounted in a local or field-mounted panel. Dashed lines indicate that the instrument is mounted inside the panel.

Usage will depend upon context. Depending on the circumstance, the third letters Control, Transmit, and Compute can also be used as a verb or noun, in which case they will appear in text or speech as Controller, Transmitter, and Computer, respectively.

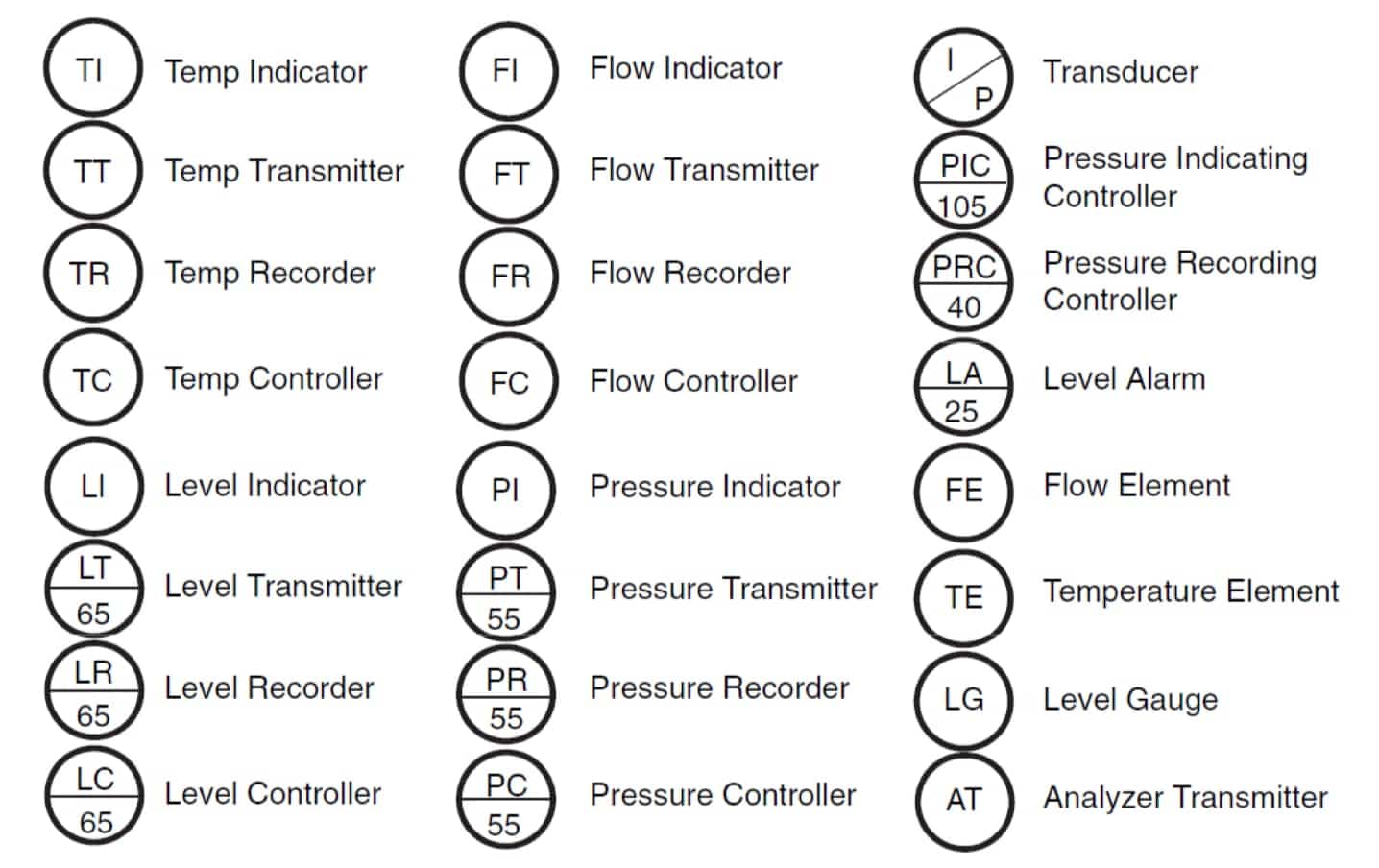

The following are a few of the more common p&id abbreviations as prefix:

- PIC = Pressure Indicating (Indicator) Controller

- LR = Level Recorder

- TT = Temperature Transmitter

- DAH = Density Alarm High

- DAHH = Density Alarm High High

- LSHH = level switch high-high

- LSH = level switch high

- LSL = level switch low

- LSLL = level switch low-low

- LAL = level alarm low

- PT = pressure transmitter

- PDT = pressure differential transmitter

- AT = analyzer transmitter

- TE = temperature element

- TT = temperature transmitter

- PDSH = pressure differential switch high

- KQL = time quantity light (i.e., time is expired)

- PY = pressure transducer

- ZSO = position switch (open)

- HV = hand valve

- HS = hand switch

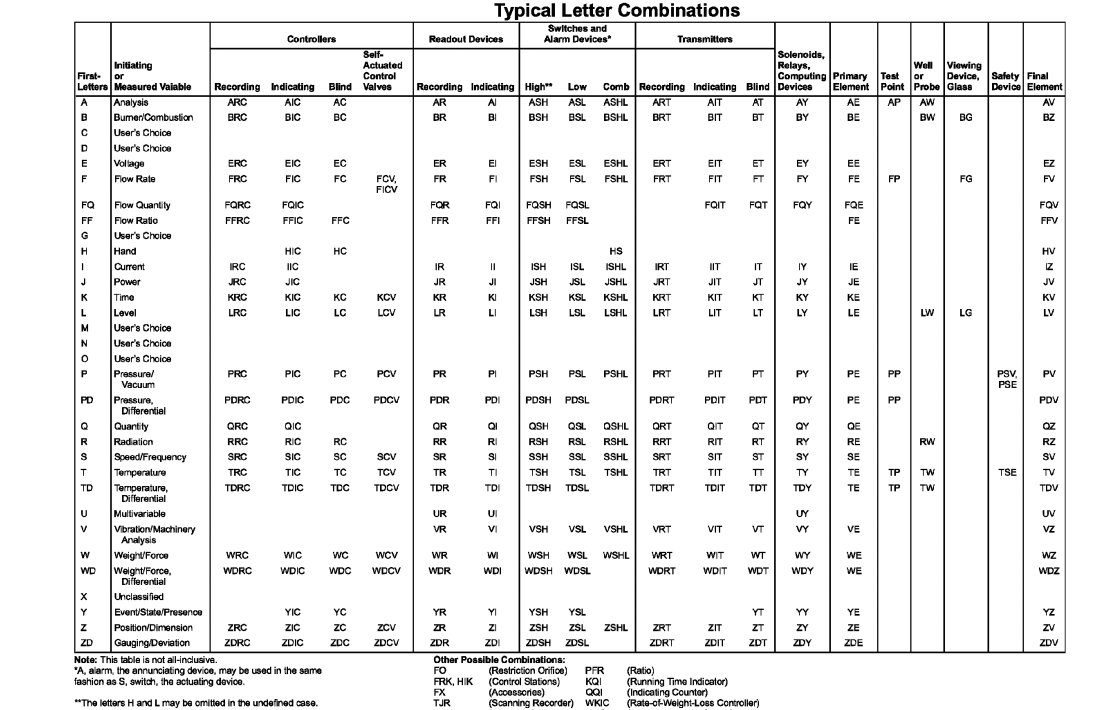

3.1.1 Typical P&ID Letter Combinations

Extended Table of typical letter combinations for instrumentation equipment:

3.2 Suffix

3.2.1 Loop Number Based

- In addition to the letters, the instrumentation and control design group assigns a sequence number to each function. All the devices within that function carry the same sequential number, the loop number. A single loop number is used to identify the devices that accomplish a single specific action usually an input and an output for P and ID control, an input for indication of a process variable, or a manual output.

- This number, combined with the letter designation, positively and uniquely identifies each device within that set.

- Numbering of elements is in accordance with some plant based convention.

- There are two approaches, serial and parallel, of which serial is the more common.

- On a serial basis each channel, loop or scheme is allocated a unique number, for example 47. Regardless of the letter code, all its elements assume the same number. By serial means using a single numerical sequence for all devices. Therefore, there may be an FRC-101, a LR-102, a PIC-103, and a TI-104.

- On a parallel basis, blocks of numbers are allocated according to instrument type or function, depending on its letter code. This results in similar elements in different loops having contiguous numbers. These numbers may follow the suggestions in ISA-5.1. By parallel, means starting a new number sequence for each first letter. Therefore, there may be an FRC-101, a PIC-101, and a TI-101.

3.2.2 Location Number Based

- The first digit of the number may indicate the plant number; hence, FT-102 is an instrument in plant 1.

- Another method of identifying the instrument location is with a prefix, for example: 2 (area), or 03 (unit), or 004 (plant 4) which identifies the service area of the loop: 2-FT-102 is loop 102 in area 2, or 03-FT-102 is loop 102 in unit 03, or 004-FT-102 is loop 102 in plant 4.

- These numbers can also be combined to show area-unit-plant in one number: 234-FT-102 is a flow transmitter in loop 102, which serves area 2, unit 3 and plant 4.

- To be completely confusing, remember that the loop number defines the items in the loop, so the loop may serve the area listed above, but a particular device may be physically located in another area.

3.2.3 P&ID Diagram Number Based

- A variation of this system is to tie the P&ID numbers to a particular area, and then to sequentially number the instruments on that P&ID sheet. For example, P&ID 25 carries up to 100 loops, or instrument loop numbers 2500 to 2599.

- The elegance of this system is that you can find the correct P&ID for an instrument based upon the tag number alone, since the tag number includes the P&ID number.

- Frequently the area number is nested in the P&ID number anyway, so you will also know the area served by the loop just by looking at the loop number.

3.2.4 Major Equipment Designation Based

- The destination that appears in the loop number place on the instrument circle is an equipment identifier that is tied to a master equipment designation table.

- Conventions Used for Identifying Process Equipment:

- Process Equipment General Format XX-YZZ A/B

- XX are the identification letters for the equipment classification:

- C Compressor or Turbine

- E Heat Exchanger

- H Fired Heater

- P Pump

- R Reactor

- T Tower

- TK Storage Tank

- V Vessel

- Y designates an area within the plant

- ZZ is the number designation for each item in an equipment class A/B identifies parallel units or backup units not shown on a PFD.

- Additional description of equipment given on top of PFD.

Table is based on ISA-5.1-1984 (R1992)

Typical p&id letter combinations are shown in the following table, the table is based on ISA-5.1-1984 (R1992):

| FIRST LETTER | MEASURED OR INITIATING VARIABLE | MODIFIER | READOUT OR PASSIVE FUNCTION | OUTPUT FUNCTION | MODIFIER | |

|---|---|---|---|---|---|---|

| A | Analysis (5,19) | Alarm | ||||

| B | Burner, Combustion | Users Choice (1) | Users Choice (1) | Users Choice (1) | ||

| C | Conductivity | Control (13) | Close | |||

| D | Density/Sp. Gravity | Differential (4) | Deviation | |||

| E | Voltage | Sensor (Primary Element) | ||||

| ESD | Emergency Shutdown | |||||

| F | Flow Rate | Ratio (Fraction) (4) | ||||

| G | Gaging | Sight Glass, Viewing Device (9) | ||||

| H | Hand (manual) | High (7, 15, 16) | ||||

| HH | High High | |||||

| I | Current (Electrical) | Indicate (10) | ||||

| J | Power | Scan (7,24) | ||||

| K | Time, Time Schedule | Time Rate of Change (4,21) | Control Station (22) | |||

| L | Level | Light Pilot (11) | Low (7,15,16) | |||

| LL | Low Low | |||||

| M | Moisture | Momentary (4, 25) | Middle, Intermediate (7,15) | |||

| N | Users Choice (1) | Users Choice (1) | Users Choice (1) | Users Choice (1) | ||

| O | Users Choice (1) | Orifice, Restriction (23) | Open | |||

| P | Pressure, Vacuum | Point (Test) Connection (26) | ||||

| Q | Quantity/Event | Integrate, Totalize (4) | ||||

| R | Radiation | Ratio | Record or Print (17) | |||

| S | Speed, Frequency | Safety (8) | Switch (13) | |||

| T | Temperature | Transmit (18) | ||||

| U | Multivariable (6) | Multifunction (12) | Multifunction (12) | Multifunction (12) | ||

| V | Viscosity, Vibration, Mechanical Analysis (19) | Valve, Damper, Louver (13) | ||||

| W | Weight, Force | Well or pocket | ||||

| X | Unclassified (2) | X Axis | Unclassified (2) | Unclassified (2) | Unclassified (2) | |

| Y | Event, State or Presence (20) | Y Axis | Relay, Compute, Convert (13, 14, 18) | |||

| Z | Position, Dimension | Z Axis | Driver, Actuator, Unclassified Final Control Element |

Notes:

- A first letter used with a modifier is treated as a first-letter entity. Example: TDI for differential temperature.

- To cover all analysis not described by a users choice letter. The type of analysis must be defined outside the tagging bubble.

- To be used in lieu of a combination of first letters. Generally used for multipoint record- ers/indicators.

- Using these modifiers is optional. Example: The letters H and L may be omitted in the undefined case.

- To cover only emergency protective primary elements, such as a rupture disk (PSE), and emergency protective final control elements, such as a pressure safety valve (PSV).

- Applies to instruments that provide an uncalibrated view, such as a sight-glass level gage (LG) and television monitors.

- Normally applies to analog or digital readout.

- Used for pilot lights. Example:A running light for a motor maybe identified as EL or YL, depending on whether the measured variable is voltage or operating status, respectively. Used also for process indicating light. Example: A high-level light (LLH).

- Used instead of a combination of other functional letters.

- Used for hand-actuated switches or on-off controllers.It is incorrect to use the succeeding letters CV for anything other than a self-actuated control valve.

- Used generally for solenoid devices and relays. For other uses, the meaning needs to be defined outside the tagging bubble.

- These modifying terms correspond to values of the measured variable, not to values of the signal. Example: A high level from a reverse-acting level transmitter should be LAH.

- The terms high and low when applied to positions of valves denote open and closed positions, respectively.

- Applies to any form of permanent storage of information.

- Used for the term transmitter.

- Used to perform machine analysis(where as the letter A performs more general analyses). Except for vibration, the meaning must be defined outside the tagging bubble.

- Not to be used when control or monitoring responses are timed rive nor time/schedule driven.

- To signify a time rate of change of the measured variable.Example:WKIC means a rate- of-weight-loss indicating controller.

- Used to designate an operators control station, such as a manual loading station(HIK), or the operator interface of a distributed control system.

- Used also to designate a restriction orifice(FO).

- Used also to designate a temperature-scanning recorder(TJR).

- Used also to designate a hand momentary switch(HMS).

- For example, an analysis test point is identified as AP.

Extra Rules:

- There are several letters - C, D, G, M, N, O, which can be specified by the user.

- The second column, marked Modifier, adds additional information about the first letter, the process variable. For example, if an instrument is used to measure the difference between two pressures, perhaps the upstream and downstream pressure of a filter press, a P for pressure is used as the first letter and a D for differential as a second letter modifier. When instantaneous flow is being measured and a totalizer is added to provide total flow over time, the device identification is FQ. The first letter of the tag name is F for flow and the second letter is Q from the second column, signifying integrate or totalize.

- The next three columns further define the device. The first of these delineates a readout or passive function.

- The meanings need be defined only once. A users choice letter is intended to cover unlisted meanings that will be used repetitively in a particular project. If used, the letter may have one meaning as a first-letter and another meaning as a succeeding-letter. The meanings need to be defined only once in a legend, or other place, for that project.

- An S as a second letter can be a modifier for the first letter, or it can be classified as a succeeding letter. This can be a bit confusing. If S is used as a succeeding letter, it applies to emergency protective primary elements. In this case, a device normally labeled PCV could also be labeled PSV if it is used as a safety device. The term x