P&ID Symbol Diagram Basics - Part 1

Purpose, Owner & Contents

1.P&ID

Welcome to our Engineering and P&ID Diagrams resource page. Here, you'll find key insights into the world of Process and Instrumentation Diagrams (P&ID) a foundational tool in engineering that helps bring complex processes to life through precise and detailed visualization. Whether you're new to P&IDs or looking to deepen your understanding, our resources are designed to guide you through essential concepts, industry standards, and best practices. For a more comprehensive exploration of related topics, we invite you to visit the links provided below. Each link offers further information on crucial aspects of engineering and process design that complement and enhance your knowledge of P&ID diagrams.

- If you are interested to know more about subjects like Standards and Guidelines read our free introduction to these concepts in our article P&ID Diagram Basics - Part 2 - International Standards.

- If you are interested to know more about subjects like Functional Identification and Instrument Numbering read our free introduction to these concepts in our article P&ID Diagram Basics - Part 3 - Functional Identification and Naming Conventions.

- If you are interested to know more about subjects like P&ID Symbols read our free introduction to these concepts in our article P&ID Diagram Basics - Part 1 - Symbols - How to read a P&ID.

Piping and instrumentation diagram (P&ID) has a fundamental importance in process automation and process industry. It gives an overall view of the entire process loop of the facility. The Automation, Systems and Instrumentation Dictionary in its 4th edition defines what Piping and Instrumentation Drawing do: P&IDs show the interconnection of process equipment and the instrumentation used to control the process.

They are used as an element of communication between engineering, plant operation, maintenance and construction, since they show detail information of the plant relating to equipment, pipeline, instrumentation and common services. P&ID must be maintained accurately and updated.

The creation of the instrumentation diagram or p&id constitutes an important phase in the design of a process plant.

It is a diagram of the systems / equipment present in a section of the plant.

It shows the necessary graphical elements to execute, monitor and control specific processes.

The P&ID drawing does not describe the chemical reactions involved in the process nor does it describe procedures of the same.

It is an essential document in the process industry.

Any change made in the process must be reflected in the diagram, for example if an additional pump is installed, it is important because your safety and that of your collaborators could depend on this action.

From the point of view of the control, they show information related to the control loops, although it is not always possible to represent the entire control structure. To maintain clarity and save space in these diagrams, the complex logic is not shown, it is shown in the logic diagrams ISA-5.2-1976 (R1992).

From engineering point of view, Piping and instrumentation diagrams (P&IDs) are the foundation of the E/I&C (electrical/instrumentation and control) engineering package of deliverables.

A P&ID is a diagram that shows condensed information from multiple specialties.

This type of documents (the P&ID drawings) show, from the point of view of the process, different measures such as pressure, flow, level, etc. and their respective control schemes in relation to the elements of the plant and its interconnection pipes. These elements (mechanical equipment, piping, piping components, valves, equipment drivers and instrumentation and controls) are represented by symbols and labels. A standard set of symbols is used to prepare drawings of control systems and processes. Symbols have been developed to represent all of the components used in industrial processing, and have been standardized by ANSI and ISA.

The process equipment is shown using basically symbols such as bubbles (circles or balloons) and others to indicate valves, actuators, flow meters, etc

These symbols are assembled on the drawing in a manner that clearly defines the process.

The symbols used in these diagrams are based on the following standards :

- Standard ANSI / ISA-5.1-1984 (R1992) Symbols and identification of instrumentation, this standard was developed by ISA-The Instrumentation, Systems and Automation Society (ISA) and the American National Standards Institute (ANSI).

- Standard ISA 5.31983, Graphic Symbols for Distributed Control/Shared Display Instrumentation Logic, and Computer Systems.

In some cases, the control schemes are too complex to be shown in a P and ID drawing, in this case, independent functional control diagrams are created.

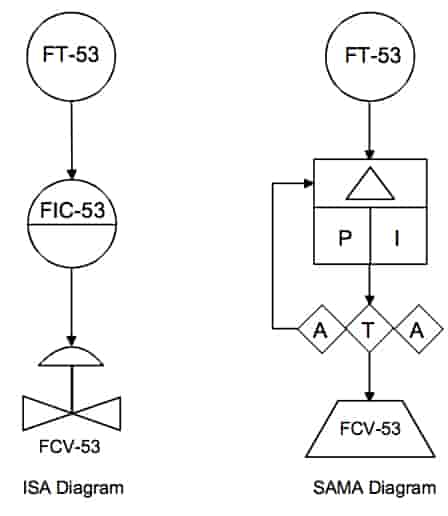

For the design of specific diagrams it is possible to use the ISA symbology or SAMA symbology (The Association of Scientific Apparatus Manufacturers withdrew and no longer supports its standards, they are available only for historical purposes and general information).

Although the P&ID is the overall document used to define the process, the first document developed in the evolution of a process design is often the PFD (Process Flow Diagrams). Once a PFD is released for detail design, the project scope has been established and P&ID development may commence.

1.1. What is P&ID?

Pronounced as P.N.I.D

There is no universal standard that specifies the meaning of the letters P&ID. Usually, for example, the P in P&ID can mean Pipe, Plant or Process. The I refers to Instrument or Instrumentation. The D is for Drawing or Diagram

Although the final format is the same for all cases, the different names given to this type of diagram are shown below:

- Pipe Diagrams and Instrumentation Diagram

- Process and Instrumentation Diagram

- Piping and Instrumentation Diagram

In this post, for simplicity, we will refer to the document by the acronym, P&ID.

2.What is P&ID used for?

The objective of the P and ID diagram is to show the necessary information in order to understand the relationship between the conceptual design of the process, developed through the PFD and HMB diagrams, with reality.

2.1. At design stage:

- Defines the design basis for Piping and Instrumentation disciplines.It is used as a document that defines the base process, from which all the engineering, manufacturing, construction and operation will be developed.

- Serves to show and agree the operating and maintenance features between Engineer and Owner or between Engineer and Vendor.

- Serves to show the interface with equipment/package vendors.

- Perform HAZOP design/review. It is used as a reference document for the management of process safety information (PSI) in Process Safety Management (PSM).It allows obtaining the necessary information to be able to analyze the hazards of the process, the potential failures and the existing safeguards in order to minimize the greatest number of errors in operation, design or humans.

2.2. During operation:

- Reference diagram for operator, work permit, plant modifications etc.

- Process technicians use P&IDs to identify all of the equipment, instruments, and piping found in their units.

- New operators or technicians use these drawings during their initial training period. Knowing and recognizing these symbols is important for a new operator/technician.

- Train Process Operators. Part of the training would pose situations and require the operators to be able to describe what specific valve should be changed, how it should be changed, and what to observe in order to monitor the effects of the change.

- Support document in the development of operation and maintenance procedures.

- Development of start-up/stop procedures where the plant is not under the influence of the installed process control systems.

- During SAT, as a checklist against which each item in the plant is checked.

- Instrumentation and Control Systems Maintenance. The process and instrumentation or piping and Instrumentation diagram (P&ID) is probably the document most used by instrumentation and control system maintenance personnel.

- Instrumentation engineering. The P&ID diagram is the main and almost ideal document to synthesize all required measurement and control functions.

The P&ID is the last stage of the design of the plant, and therefore serves as a guide for those who will be responsible for the final design and construction.

- Mechanical engineers and civil engineers will design and install pieces of equipment.

- Instrument engineers will specify, install, and check control systems.

- Piping engineers will develop plant layout and elevation drawings.

- Project engineers will develop plant and construction schedules.

3.Owner

The P&ID is the daughter of the Process Flow Diagram (PFD), a mechanical discipline product, and the heat and material balance (HMB) sheet, a process engineering product.

They are usually constituted by process engineers and control engineers during the design and construction of the plant, with the process engineers being the persons authorized to validate the changes.

The owner of the P&ID is usually the Process Engineer or Operation Responsible.

This individual or group coordinates the information that is placed in the diagram to ensure that it is consistent with the purpose of the document.

This coordination is required to regulate the information provided by the different departments towards this document.

Below is a list of some of the different specialties within the engineering that provide information for it to be reflected in this diagram:

- Process Engineering: diagram content, process data, vendor equipment depiction.

- Mechanical Engineering: pipe ID (identification, not inside diameter) numbers, equipment numbers and labels, graphical depiction of equipment and piping.

- Instrumentation Engineering: instrument numbers; graphical presentation of instruments and instrument wiring/tubing, Type of Instruments.

- Controls/Systems Engineering: control logic depictions, Communications among Control Systems.

- Electrical Engineering: motor ratings, motor wiring depictions.

Usually the creation and maintenance of this type of diagram is the responsibility of the mechanical department.

4.What is P&ID used for?

4.1 What is included in a P and ID?

A P&ID diagram is a complex representation of the various production units found in a plant.

It is used by people from different disciplines.

The main users of the document after the start-up of the plant are the process technicians and instrument and electrical, mechanical, safety, and engineering personnel.

This section will aid in solving the long existing and continuing problem of confusing information on PIDs. The fact that there is confusion can be understood because there really is no universal, national or international, multidiscipline standard that covers the development and content of P&ID and specifies what information should be included on a P and ID or even, for that matter, the meaning of the letters P and ID.

All control function directly connected to the process shall be shown on P&ID.

The P and ID diagram is a graphic index of all the main process equipment, and all the main sections of pipe instruments, and shows their functional relationships.

P&ID typically show the following types of information:

4.1.1. The process / piping part includes:

- Major and minor equipment present in process/plant such as vessels, drums, pumps, reactors ... showing

- Name and Number

- Location

- Capacity

- Pressure

- Liquid Level

- Usage

- Spare units

- Parallel units

- Summary details of each unit

- All piping and transport equipments for process and utility fluids. Including

- Specification of Materials of construction

- Identification of the pipe

- Flow directions

- Size of the pipe, Schedule (thickness)

- Insulation (thickness and type). Information relative to insulation (hot or cold) and tracing of pipes or equipments.

- Safety devices.

- Include Drains, Sample Connections

4.1.2. The Electrical & Instrumentation part includes:

- All motors, giving voltage, power, and other relevant information like buttons used to control them.

- All required function to control the process like Indicators, Recorders, Controllers , including:

- Measurement technology (graphical symbols of instruments)

- Location of instrument

- Major function

- Process control loop number

- Range

- System used to perform automation task (local instrument, DCS, PLC...)

- All control valves, giving

- Type of control

- Type of valve

- Type of valve action

- Fail-save features

- Actuator technology (graphical symbols of valves)

- Communication link between instruments systems and actuators (electric, digital pneumatic/hydraulic).

- Flow and pressure information

- Self controlled valves

- Main instruments required to perform these functions (Essential items to understand the functionalities required).

- All safety valves and pressure regulators, giving temperature and operating ranges

- Interlocks and safety related functions

According to plant size, it will be represented on one to many P&I diagrams. Generally, plants are divided in several areas, each area corresponding to one or more P&IDs diagrams. It is recommended to extend the P&ID approach for other parts or system than Process.

- Fire and Gas detection systems: P&I based on Layout drawings showing gas, fire or smoke detectors, emergency button ...

- Fire protection systems

- Package equipments

- Analyzers

4.2. Conventions in Constructing Piping and Instrumentation Diagrams

There are no universal standards that address the format to be used in developing P&IDs. The format used by most design groups has been developed over many years. However, here are a few guidelines that serve as a simplistic de facto standard:

- The devices are represented as icons. An item is shown only in one P&ID.

- Normally the plant layout of the equipment as well as the PFD is shown from left to right.

- The process flows from the left of the P&ID to the right.

- P&IDs are developed as D size sheets (22" x 34") or larger, but should be legible when reduced to B size (11" x 17") for ease of use in the office and in the field.

- P&IDs should show sufficient information to define the process without crowding. One to three pieces of equipment with auxiliaries is normally sufficient for one P&ID.

- P and ID diagrams do not usually use colors to indicate or convey their meaning. Colors are used at the design level in a monitor but are usually printed in black and white.

- To reduce clutter, a typical detail can be used for repeated components (see the typical drain on Figure 2-21).

- When piping gets complex, auxiliary P&IDs are used.

- Add notes for understanding and clarity.

- Show relative sizes of equipment, but do not include specific elevations or dimensions. They do not show the scale of the elements or their geometry. They also do not show information regarding the orientation of the team or its actual location.

- Every set of P&IDs should include a legend sheet, or sheets, to define the symbols and abbreviations used.

- The free space on a P&ID should facilitate addition of future process changes; it is best not to start with congested P&IDs.

- The pneumatic piping is shown where the information is important to communicate the functionality of the controls, and the information of the electrical wiring is presented (in the form of dotted lines) to communicate the functional intention to the electrical and instrumentation disciplines.