Introduction to Hazop Methodology, using Hazop Full form

Summary

1. Definitions

1.1. Hazard

Potential source of harm. Deviations from design or operational intent may constitute or produce a hazard. Hazards are the focus of HAZOP Analysis, and it should be noted that a single process hazard could potentially lead to multiple forms of harm.

1.2. Harm

Physical injury or damage to the health of people or damage to property or the environment. Harm is the consequence of a hazard occurring and may take many forms: patient or user safety, employee safety, business risks, regulatory risks, environmental risks, etc.

1.3. Risk

Combination of probability of occurrence of harm and the severity of that harm. In a strict sense, risk is not always explicitly identified in HAZOP studies since the core methodology does not require identification (also referred to as rating) of the probability or severity of harm. However, risk assessment teams may choose to rate these factors in order to further quantify and prioritize risks if needed.

1.4. Incident

An undesired circumstance that produces the potential for an accident.

1.5. Accident

An undesired circumstance that results in ill health, damage to the environment, or damage to property.

2. Hazop Meaning

The HAZOP analysis technique (Hazard Operability study) is generally considered to have originated in the Heavy Organic Chemicals Division of ICI, which was then a major British and international chemical company. This is a kind of process hazard analysis.

ICI was formed in 1926 by the merger of the United Kingdoms four largest chemical companies. The dominant partner was Brunner-Mond which had been founded in 1874 by Ludwig Mond and John Brunner to manufacture sodium carbonate in Northwich, Cheshire.

HAZOP analysis (Hazard Operability study) studies were developed in ICI in 1963 and the first paper on them was published in 1974 (Lawley, 1974). They have been used extensively by many companies around the world. Acceptance and propagation in the industry due to:

- Rigorous character: structured, systematic and exhaustive.

- Easy to learn and apply.

- Adaptable to most operations in the process industries.

- Does not require a specific academic level.

- Allows the exchange of experience and knowledge of the engineers involved.

- Helps to anticipate potential accidents.

They started with a technique called critical examination which asked for alternatives, but changed this to look for deviations. The method was further refined within the company, under the name operability studies, and became the third stage of its hazard analysis procedure (the first two being done at the conceptual and specification stages) when the first detailed design was produced.

The Hazop Analysis is a type of process hazard analysis (hazop pha).

2.1. What is Process Hazard Analysis (PHA)?

Is a set of organized and systematic assessments of the potential hazards associated with an industrial process.

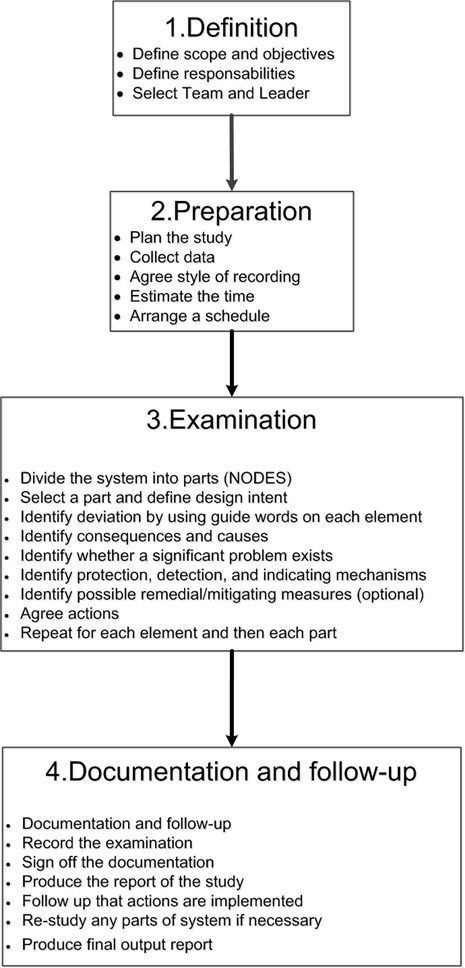

3. How to do a Hazop Analysis? HAZOP Assessment Study Procedure

4. Definition

4.1. Objectives Scope

The concept involves investigating (with a process safety perspective) how the plant might deviate from the design intent. HAZOP Analysis is an identifying technique and is not intended as a means of solving problems. The risk assessment team must identify the assessment scope carefully in order to focus effort. This includes defining study boundaries and key interfaces as well as key assumptions that the assessment will be performed under.

- Identify hazards in facilities.

- Evaluate design and operation from a safety point of view.

- Define means of prevention / protection to reduce risks to an acceptable level.

- Optimize the distribution of these means.

- Define actions priorities to improve facilities.

The purpose of HAZOP Analysis is not only to identify the hazards inherent in a particular process, but also to identify problems of operation which although not dangerous could compromise the ability of the plant to achieve its planned productivity.

4.2. Risk Assessment Team

The HAZOP Analysis (Hazard Operability study) consists of reviewing a Process in one or more meetings (HAZOP sessions) during which a multidisciplinary working group investigates in a systematic and structured way how the process can be diverted with respect to the intention of the design.

The sessions are led by an animator (leader HAZOP Analysis) who is responsible for ensuring that the methodology is applied correctly. Each member of the Hazop Analysis team contributes, responding to the questions raised, which are structured from guiding words.

The Risk Assessment Hazop Analysis Team must function competently as a group, incompatibilities can result in dysfunctional teams. Quality depends on the individual and Hazop Analysis team competence of participants.

The leader of the team should be highly familiar with the HAZOP Analysis procedure and should have excellent committee management skills. HAZOP Analysis Team leaders, should be certified or accredited by external organizations.

The Hazop Analysis team then determines what are the possible significant Deviations from each intention, feasible Causes and likely Consequences.

Minimal requirements :

- Expertise in engineering and process operations.

- At least one employee who has experience and knowledge specific to the process being evaluated.

- At least one Hazop Analysis Team Member who has knowledge in the specific PHA (Process Hazard Analysis) being used.

- Expertise in safety instrumented systems.

4.3. When to perform a HAZOP Analysis?

- At the initial concept stage when design drawings are available.

- When the final piping and instrumentation diagrams (P&ID) are available.

- During construction and installation to ensure that recommendations are implemented.

- During commissioning.

- During operation to ensure that plant emergency and operating procedures are regularly reviewed and updated as required.

5. Preparation

General company governing documents:

- Company management philosophies.

- Company operation and maintenance philosophies.

- Company modification and MoC philosophies.

- Company guidelines for implementation and follow-up of SIS.

- Company performance standards and acceptance criteria.

Hazop Analysis Documentation Requirements:

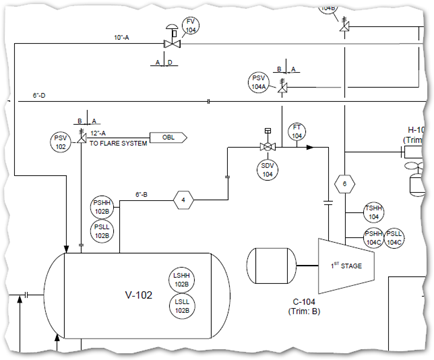

The following documents are essential at the start of a Hazop Analysis study, with the P&ID being the principal document:

- Process and instrumentation diagrams (P&IDs).

- A copy in A3 for each assistant (1 copy master in A1 to mark nodes, to be included in final report).

- Process flow diagrams (PFDs).

- General arrangement drawings.

- Relief/venting philosophy.

- Chemical hazard data.

- Piping specifications.

- Process data sheets.

- Previous safety Purpose of Hazop Analysis study reports.

Other desirable documents include:

- Operation and maintenance instructions.

- Safety procedure documents.

- Vendor package information.

- Piping isometrics.

6. Examination

The study is carried out systematically at key points of the installation (nodes) and consists of investigating the deviations of the process from the intention of the design.

6.1 Procedure

- Based on P&ID, divide the system into sections (exchanger, separator,...).

- Select a study node.

- Identify the design intent.

- Choose a process parameter.

- Apply a guide-word.

- Identify cause(s).

- Evaluate problems.

- Actions: What? When? Who?.

- Log information.

- Repeat procedure (from step 2).

Design intent is the group of required behaviors for the process, is a description of how the process is expected to behave at the node.

Deviations are obtained by applying some guiding words to certain process parameters. Unexpected events or consequences are identified.

The effectiveness of safeguards is reviewed. For scenarios whose risk is considered not tolerable, additional studies or actions are required.

Once we have all the needed information and the team is ready to start, the first thing we must do is define the list of nodes.

6.2 Node Definition

- Due to it is impossible to simultaneously analyze all possible deviations of a process, it is subdivided into nodes (manageable units / subsections).

- There is no clear and unique methodology to do the nodes definition. A node is a section of the process where a physical or chemical change occurs.

- Basic definition: elements of the installation or phases of the operation that share similar design intentions. Nodes are often defined by grouping similar processes that use the same or similar equipment. For example, a node may consist of a reactor and key associated equipment, or the raw materials supplied to that reactor system.

- Nodes are defined following the process flow, from upstream to downstream.

For continuous processes, a node can be:

- One equipment (reactor, exchanger, separator)

- A line or part of a line with constant conditions (upstream of an exchanger, after a pressure valve, etc.)

- A transient operation (commissioning, stoppage, sampling ...)

- A support operation (maintenance, equipment test, ...)

For batch processes, a node can be:

- A stage of the operation: cleaning, inertization, heating, cooling, ...

- One phase of the process: reagent loading, product discharge ...

- A specific operation: test, maintenance, sampling ...

The following modes of plant operation should be considered for each node:

- Normal operation.

- Reduced throughput operation.

- Routine start-up.

- Routine shutdown.

- Emergency shutdown.

- Commissioning.

- Special operating modes.

6.3 Deviations

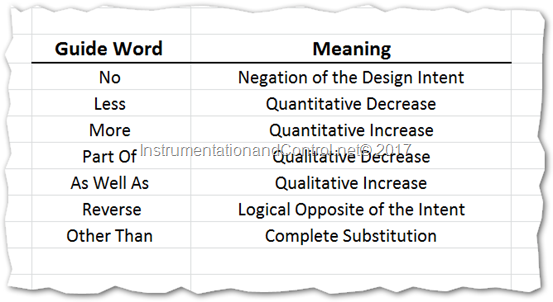

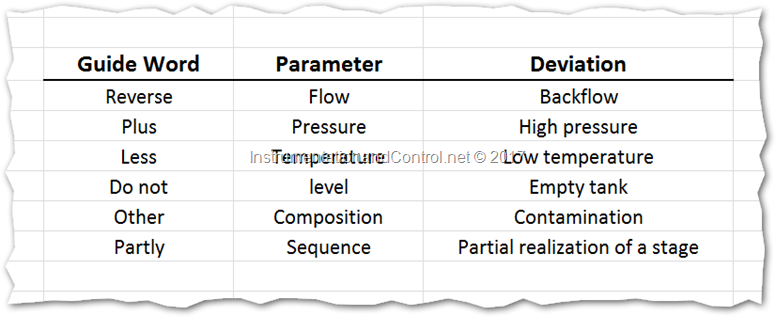

6.3.1 Guide Word:

A short word to create the imagination of a deviation of the design/process intent. The most commonly used set of guide words is: no, more, less, as well as, part of, other than, and reverse. In addition, guide words like too early, too late, instead of, are used; the latter only for batch-like processes. The guide words are applied, in turn, to all the parameters, in order to identify unexpected and yet credible deviations from the design/process intent. The Hazop Analysis guide words, work by providing a systematic and consistent means of brainstorming potential deviations to operations.

The guide words are then applied to each of the identified nodes.

6.3.2 Parameter:

Process parameters may generally be classified into the following groups:

- Physical parameters related to input medium properties.

- Physical parameters related to input medium conditions.

- Physical parameters related to system dynamics.

- Non-physical tangible parameters related to batch type processes.

- Parameters related to system operations.

These parameters are not necessarily used in conjunction with guide words:

- Instrumentation.

- Relief.

- Start-up / shutdown.

- Maintenance.

- Safety / contingency.

- Sampling.

6.3.3 Deviation:

A deviation is a way in which the process conditions may depart from their design/process intent. They are the key element of the methodology. They are systematically identified by the coherent combination of one guideline plus one parameter.

According to IEC Standard 61882:

The identification of deviations from the design intent is achieved by a questioning process using predetermined guide words. The role of the guide word is to stimulate imaginative thinking, to focus the study and elicit ideas and discussion.

In this fashion a thorough search for deviations is carried out in a systematic manner. It must be noted that not all combinations of guide words and elements are expected to yield sensible or credible deviation possibilities. As a general rule, all reasonable use and misuse conditions which are expected by the user should be identified and subsequently challenged to determine if they are credible and whether they should be assessed any further. There is no need to explicitly document the instances when combinations of elements and guide words do not yield any credible deviations.

6.4 Causes and Consequences

6.4.1 Causes

Flow High

- Increased pumping capacity.

- Increased suction pressure.

- Reduced delivery head.

- Greater fluid density.

- Exchanger tube leaks.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point,...).

- Dynamic equipment fault: pump, compressor, fan.

- Start up of a second dynamic unit.

- Decrease of downstream pressure.

- Upstream pressure rise.

- Opening of a manual / automatic valve.

- Opening of a PSV or rupture disk.

- Fluid input by:

- Unwanted inputs.

- Leak in the wall (shirt, exchangers ...).

- Human error.

- Restriction orifice plates not installed.

- Cross connection of systems.

- Control faults.

- Control valve trim changed.

- Running multiple pumps.

Flow Less

- Restriction.

- Wrong routing.

- Filter blockage.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Dynamic fault / stop: pump, compressor, fan.

- Cavitation.

- Lack of product in the food.

- Increase pressure downstream.

- Decrease of upstream pressure.

- Closing a manual / automatic valve.

- Limitation or stoppage of the flow by:

- Presence of gas bag.

- Depositions, foreign bodies, crystallizations.

- Fluid outputs by:

- Unwanted outputs.

- Leak in the wall (shirt, exchangers ...).

- Defective pump(s).

- Fouling of vessel(s), valves, orifice plates.

- Density or viscosity changes.

- Cavitation.

- Drain leaking.

- Valve not fully open.

Flow None

- Wrong routing.

- Blockage.

- Incorrect slip plate.

- Human error.

- One-way (check) valve in backwards.

- Pipe or vessel rupture.

- Large leak.

- Equipment failure.

- Isolation in error.

- Incorrect pressure differential.

- Gas locking.

Flow reverse

- Defective one-way (check) valve.

- Siphon effect.

- Incorrect pressure differential.

- Two-way flow.

- Emergency venting.

- Fluctuations in equipment pressure.

- Fluctuations in pressure of connected neighbor equipment.

- Leakage in non-return valve or shut-off valve.

- Stop of a dynamic equipment: pump or compressor.

- Drain leaking.

- Mounting error.

- Opening / closing of a manual / automatic valve.

- Unwanted fluid input through another circuit.

- Incorrect operation.

- Inline spare equipment.

- Pump failure.

- Pump reversed.

Level High

- Outlet isolated or blocked.

- Inflow greater than outflow control failure.

- Faulty level measurement.

- Gravity liquid balancing.

- Flooding.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Excessive regular supplies.

- Insufficient outputs:

- Closing valve.

- Obstruction, presence of foreign body.

- Unwanted inputs from other circuits.

- Service fluid inlet (water, steam, oil ...).

- Variations in temperature or pressure.

- Abnormally reduced density.

- Presence of foam, condensation, eddies.

- Human error.

- Pressure surges.

- Corrosion.

- Sludge.

Level Low

- Inlet flow stops.

- Leak.

- Outflow greater than inflow.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Excessive habitual outputs.

- Insufficient inputs:

- Closing of valve.

- Obstruction, presence of foreign body.

- Unwanted outputs from other circuits.

- Exits by the lines of service fluids (water, steam, oil ...)

- Leakage to the outside.

- Variations in temperature or pressure.

- Abnormally high density.

- Vaporizations.

- Human error.

- Control failure.

- Faulty level measurement.

- Draining of vessel.

- Flooding.

- Pressure surges.

- Corrosion.

- Sludge.

Pressure High

- Surge problems.

- Connection to high pressure.

- Gas (surge) breakthrough.

- Inadequate volume of vents.

- Incorrect vent set pressure for vents.

- Relief valves isolated.

- Thermal overpressure.

- Positive displacement pumps.

- Failed open PCV.

- Boiling.

- Freezing.

- Chemical breakdown.

- Priming.

- Exploding.

- Imploding.

- External fire.

- Weather conditions.

- Hammer.

- Changes in viscosity/density.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Excessive heat (jacket, resistance, pre-heat exchanger ...).

- Insufficient cooling.

- Exothermic reaction (vapor pressure) and / or producing non-condensible gases:

- Loss of control of the normal reaction.

- Secondary reaction, decomposition of products.

- Uncontrolled mixing of incompatible products.

- Stopping an endothermic reaction (vapor pressure) and / or consuming non-condensable gases.

- Excessive gas, liquid or solid feeds.

- Normal inputs: products, solvents, nitrogen ...

- Unwanted inputs.

- Insufficient or no gas, liquid or solid outlets.

- Valves closed or obstructed.

- Lines obstructed by foreign bodies, depositions, crystallizations ...

- Inverse flow in an outlet.

- Increased pressure on connected neighbor equipment.

- Scaling.

- Foaming.

- Condensation.

- Sedimentation.

- Gas release.

- Confinement between two valves and dilation due to reaction, sun, fire ...

- Loss of vacuum in vacuum equipment (system failure, leakage, valve opening ...).

- Human error.

Pressure Low

- Generation of vacuum conditions.

- Condensation.

- Gas dissolving in liquid.

- Restricted pump/compressor line.

- Undetected leakage.

- Vessel drainage.

- Blockage of blanket gas regulating valve.

- Boiling.

- Cavitation.

- Freezing.

- Chemical breakdown.

- Imploding.

- Fire conditions.

- Weather conditions.

- Changes in viscosity/density.

- Insufficient heat input.

- Excessive cooling.

- Endothermic reaction (vapor pressure) and / or consuming non-condensable gases:

- Loss of control of the normal reaction.

- Secondary reaction, absorption, adsorption.

- Uncontrolled mixing of products.

- Stopping an exothermic reaction (vapor pressure) and / or producing non-condensable gases.

- Flashing.

- Sedimentation.

- Scaling.

- Foaming.

- Gas release.

- Priming.

- Exploding.

- Insufficient or no gas, liquid or solid feed.

- Excessive gas, liquid or solid outlets.

- Normal outputs: products, solvents, nitrogen ...

- Unloading.

- Unwanted outputs.

- External leaks: leakage, rupture ...

- Opening a PSV, rupturing a disk, or reverse flow in an input.

- Decreased pressure on connected neighbor equipment.

- Decrease in ambient Tª: frost, storm, rain, ...

- Human error.

Temperature High

- Ambient conditions.

- Fouled or failed exchanger tubes.

- Fire situation.

- Reaction control failures.

- Heating medium leak into process.

- Faulty instrumentation and control.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Excessive heat (jacket, resistance, pre-heat exchanger ...).

- Insufficient cooling.

- Exothermic reaction (vapor pressure) and / or producing non-condensable gases:

- Loss of control of the normal reaction.

- Secondary reaction, decomposition of products.

- Uncontrolled mixing of products.

- Exothermic parasite reaction.

- Stop an endothermic reaction.

- Insufficient or no gas, liquid or solid feed.

- Cooling water failure.

- Defective control valve.

- Heater control failure.

- Internal fires.

- Temperature increase:

- Hot supply by another circuit.

- High ambient temperature (summer, air conditioning).

- Exposure to the sun.

- Proximity of a fire.

- Compression, mechanical wave ...

- Human error.

Temperature Low

- Ambient conditions.

- Reducing pressure.

- Opening / closing of regulating valve (sensor fault, logic, actuator, valve, change in set point, ...).

- Insufficient heat input.

- Excessive cooling.

- Endothermic reaction (vapor pressure) and / or consuming non-condensable gases:

- Loss of control of the normal reaction.

- Secondary reaction, absorption, adsorption.

- Unwanted feeding.

- Uncontrolled mixing of products.

- Stop of an exothermic reaction.

- Sudden vaporization: leakage, discharge, ...

- Decrease in temperature:

- Cold supply by another circuit.

- Low ambient temperature (winter, air conditioning).

- Fouled or failed exchanger tubes.

- Loss of heating.

- Depressurization of liquefied gas-Joule Thompson effect.

- Faulty instrumentation and control.

Part of Concentration wrong

- Leaking isolation valves.

- Leaking exchanger tubes.

- Phase change.

- Incorrect feedstock specification.

- Process control upset.

- Reaction by products.

- Ingress of water, steam, fuel, lubricants, corrosion products from high pressure system.

- Gas entrainment.

As well as Contaminants

- Leaking exchanger tubes.

- Leaking isolation valves.

- Incorrect operation of system.

- Interconnected systems.

- Wrong additives.

- Ingress of air: shutdown and start-up conditions.

- Elevation changes and fluid velocities.

- Ingress of water, steam, fuel, lubricants, corrosion.

- Products from high-pressure system.

- Gas entrainment.

- Feed stream impurities (e.g., mercury, H2S, CO2).

Other than Wrong material

- Incorrect or off-specification feedstock.

- Incorrect operation.

- Wrong material delivered.

Viscosity More

- Incorrect material or composition.

- Incorrect temperature.

- High solids concentration.

- Settling of slurries.

Viscosity Less

- Incorrect material or composition.

- Incorrect temperature.

- Solvent flushing.

Relief system

- Relief philosophy (process and fire).

- Type of relief device and reliability.

- Relief valve discharge location.

- Pollution implications.

- Two-phase flow.

- Low capacity (inlet and outlet).

Corrosion/erosion

- Cathodic protection arrangements (internal and external)

- Coating applications

- Corrosion monitoring methods and frequencies

- Materials specification

- Zinc embrittlement

- Stress corrosion cracking

- Fluid velocities

- Sour service (e.g., H2S, mercury)

- Riser splash zone

Service failures

- Instrument air

- Steam

- Nitrogen

- Cooling water

- Hydraulic power

- Electric power

- Water supply

- Telecommunications

- PLCs/computers

- HVAC

- Fire protection (detection and suppression)

Abnormal operation

- Purging

- Flushing

- Start-up

- Normal shutdown

- Emergency shutdown

- Emergency operations

- Inspection of operating machines

- Guarding of machinery

Maintenance/procedures

- Isolation philosophy

- Drainage

- Purging

- Cleaning

- Drying

- Access

- Rescue plan

- Training

- Pressure testing

- Work permit system

- Condition monitoring

- Lift and manual handling

Static

- Grounding arrangements

- Insulated vessels

- Low conductance fluids

- Splash filling of vessels

- Insulated strainers and valve components

- Dust generation

- Powder handling

- Electrical classification

- Flame arrestors

- Hot work

- Hot surfaces

- Auto-ignition or pyrophoric materials

Spare equipment

- Installed or not installed

- Availability of spares

- Modified specifications

- Storage of sp

Sampling/procedures

- Sampling procedure

- Time for analysis results

- Calibration of automatic samplers

- Reliability and accuracy of representative sample

- Diagnosis of results

Time

- Too long

- Too short

- Wrong time

Action

- Overkill

- Underestimated

- None

- Reverse

- Incomplete

- Knock-on

- Wrong action

Information

- Confusing

- Inadequate

- Missing

- Misinterpreted

- Partial

- Stress

- Wrong information

Sequence

- Operation too early

- Operation too late

- Operation left out

- Operation performed backwards

- Operation not completed

- Supplementary action taken

- Wrong action in operation

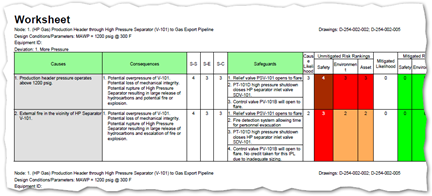

Hazop Full Form Worksheet Automated validation and testing of application logic in safety logic solvers

Safety systems

- Fire and gas detection and alarms

- Emergency shutdown (ESD) arrangements

- Fire fighting response

- Emergency training

- TLVs of process materials and method of detection

- First aid/medical resources

- Vapor and effluent disposal

- Testing of safety equipment

- Compliance with local and national regulations

Global

- Layout and arrangement

- Weather (temperature, humidity, flooding, winds, sandstorm, blizzards, and so on)

- Geological or seismic

- Human factors (labeling, identification, access, instructions, training, qualifications, and so on)

- Fire and explosion

- Adjacent facility exposures

6.4.2 Consequences

Are the physical manifestations of the undesired event (events that occur if actions are not taken to redirect the system in case of deviation).

A cause can have multiple consequences. For example, a leak of a methanol pump:

- Dispersion of toxic cloud

- Explosion of flammable cloud

- Shed to public waterway

- Stop production

Be clear and precise in their drafting (TAG, equipments, substances involved, impact ...).

The consequences should be considered in the analyzed node, but also upstream and downstream of the node.

Specify the worst possible consequences (WITHOUT considering safeguards). The consequences have to be described under the assumption that ONLY PASSIVE SAFEGUARDS are efficient, like Equipment and piping design, Firewalls, etc...

6.5 Safeguards

Definition: Any measure, whether technical, operational or organizational, that prevents the occurrence of a deviation or to mitigate its consequences.

Safeguards Types:

6.5.1 Passive

- Prevent the unwanted event (accident)

- Design Pressure of equipment

- Design temperature of equipment

- Properties of materials

- Trip of the activity

- Design of operating conditions

- Inert gas blanket in storages of flammable substances

- and Mitigate the consequences

- Toxic effects: Confinement

- Thermal Effects: Fire Resistant Walls

- Mechanical Effects: Pressure Resistant Design

6.5.2 Active

- Reduce the frequency of occurrence of the unwanted event (accident)

- Prevention of Cause: Physical interlocking

- Identification of the deviation: Process alarm, operator detection ...

- Process Controlled Deviation: Control Instrumentation, Operator Action ...

- Security Devices: SIFs, PSV and Rupture Disk

- Vent systems

- and Reduce the severity of the consequences

- Toxic effects: Cutting valves, water curtains ...

- Thermal Effects: Fire Resistant Walls

- Thermal effects: Fire protection system

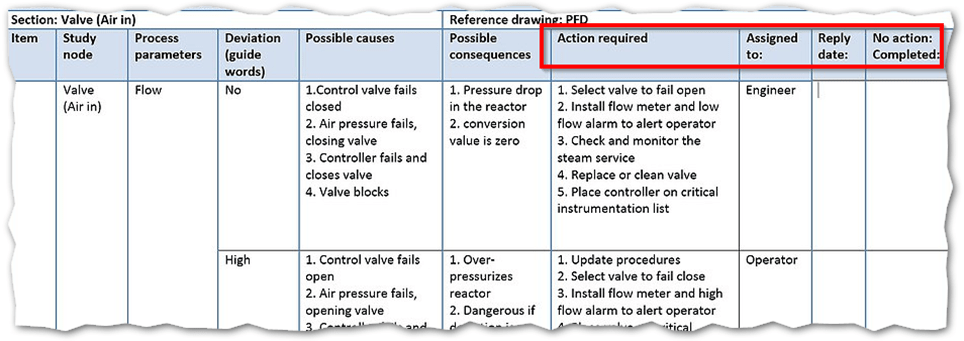

6.6 Actions

Activities / processes to be undertaken when the combination of identified impacts and existing safeguards poses an unacceptable level of risk.

They need to be clearly written, because they must be understandable by the executors. Usually this is the most popular section of the HAZOP Analysis study report. When drafting the study report, avoid imperatives and use words such as evaluate, study, verify, review .... Its mandatory to assign for every action one responsible, department, etc... Later, the project manager will define the priorities. A file of the agreed actions is needed in order to follow-up the evolution of the activities.

7. Documentation & Follow-up Phase

The documentation of HAZOP analysis is often facilitated by utilizing a template recording form as detailed in IEC Standard 61882.

Risk assessment teams may modify the template as necessary based on factors such as:

- Regulatory requirements

- Need for more explicit risk rating or prioritization (ex: rating deviation probabilities, severities, and/or detection)

- Company documentation policies

- Needs for traceability or audit readiness

- Other factors

8. Common Mistakes

- Failing to establish a safe environment for team members

- Consequences of events not carried to conclusion.

- Taking unwarranted credit for safeguards

- Too little credit given for safeguards

- Making recommendations as specific as possible

- Poor recording of HAZOPS Analysis

- Failure to Hazop Analysis start-up and shut-down procedures

- Poorly up-dated P&IDs

This article has covered the basic aspects of HAZOP Analysis.