Q1 - What is a HAZOP study in industrial safety?

A HAZOP (Hazard and Operability) study is a structured and systematic process hazard analysis technique used to assess and manage risks in industrial processes and systems. It involves a multidisciplinary team examining the design and operation of a system to identify potential hazards, deviations from the intended operation, and their consequences. The primary goal is to enhance safety by proactively identifying and mitigating risks.

Q2 - Why is a HAZOP study important in industrial safety?

HAZOP studies are crucial for industrial safety because they help prevent accidents, protect personnel, and safeguard the environment. By systematically analyzing the process and identifying potential hazards, deviations, and their consequences, organizations can implement control measures and design changes to minimize or eliminate risks. This proactive approach not only saves lives but also reduces downtime, lowers insurance costs, and maintains regulatory compliance.

Q3 - How is a HAZOP study conducted?

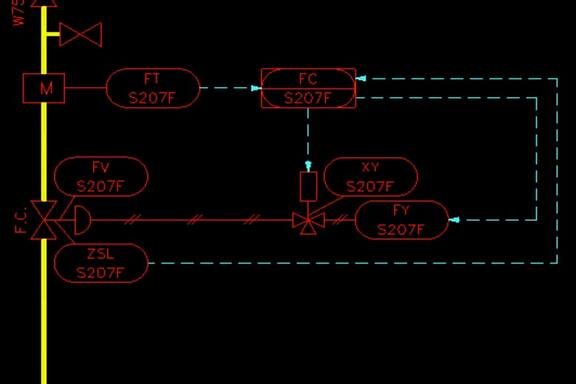

A HAZOP study typically involves a team of experts with diverse knowledge, such as process engineers, safety professionals, operators, and others. The team reviews detailed process documentation, including P&ID (Piping and Instrumentation Diagrams), and systematically applies a set of guide words (e.g., "no," "more," "less," "reverse") to identify potential deviations in parameters like pressure, temperature, flow, and level. They then assess the consequences of these deviations and propose safeguards or corrective actions.

Q4 - When should a HAZOP study be performed in an industrial facility?

A HAZOP study should be conducted at various stages in the lifecycle of an industrial process or system, including during the design, modification, and operational phases. Ideally, it should begin during the design phase to identify and address potential safety concerns early in the project. Additionally, regular periodic reviews are essential to ensure that changes or aging equipment do not introduce new hazards. Major process modifications or incidents can also trigger the need for a HAZOP review to assess the impact on safety and operations.