Industrial Engineering

Our best Industrial Engineering articles

In this section we will find articles related to instrumentation engineering in the process industry. All the articles have been written with the idea of introducing and explaining concepts related to instrumentation engineering in the process industry. Each article has a version prepared in pdf format for download and dissemination. If you have any questions or require further clarification, do not hesitate to contact us.

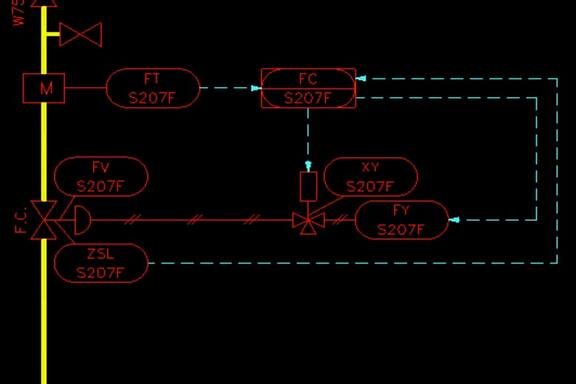

Introduction to Instrumentation

This article provides a basic introduction to process control based on the differentiation between an open control loop and a closed control loop. This fundamental idea is part of the pillars of process control.

Instrument Selection Principles

This article describes the static and dynamic characteristics of instruments. It allows you to understand the difference between the different concepts related to the specification of an instrument, online analyzer or sensor.Knowing the meaning of each of these parameters or characteristics allows us to compare the performance of different instruments when we want to select one of them to perform a certain function.